Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

How do you cut through the noise and select the right workhorse for your business? The key lies in understanding a few critical factors.

The 4-Step Selection Checklist

1. Understand Your Air Demand (CFM):

This is your most important number. Calculate the total Cubic Feet per Minute (CFM) required by all the tools operating simultaneously. Always add a 15-20% safety margin for future expansion and leaks. Under-sizing is the most common and costly mistake.

2. Determine the Necessary Pressure (PSI/Bar):

Check the required operating pressure of your most demanding tools. Most industrial equipment needs 100-150 PSI (7-10 Bar). Ensure your compressor can deliver pressure at least 10-20 PSI higher to account for pressure drops in the lines.

3. Evaluate Your Power Supply:

Smaller units may run on single-phase power, but for robust, continuous operation, a three-phase power supply is the industry standard for its efficiency and motor longevity.

4. Analyze Your Duty Cycle:

Do you run your tools intermittently or for hours on end?

Reciprocating (Piston) Compressors: Ideal for intermittent use (e.g., 60-70% duty cycle).

Rotary Screw Compressors: Built for continuous, 100% duty cycle operation.

While a standard single-stage piston compressor might seem sufficient for basic tasks, businesses focused on growth and efficiency are quickly realizing there's a smarter, more durable solution.

The Smart Upgrade: Why Two-Stage Compression is a Game Changer

Imagine if you could lower your biggest operational cost—your electricity bill—while simultaneously getting a more reliable machine. This isn't a paradox; it's the fundamental benefit of a two-stage air compressor.

In a two-stage design, air is compressed in two steps:

Stage 1: Air is compressed to an intermediate pressure and cooled.

Stage 2: The pre-cooled air is compressed to its final pressure.

This simple "cooling interlude" makes all the difference.

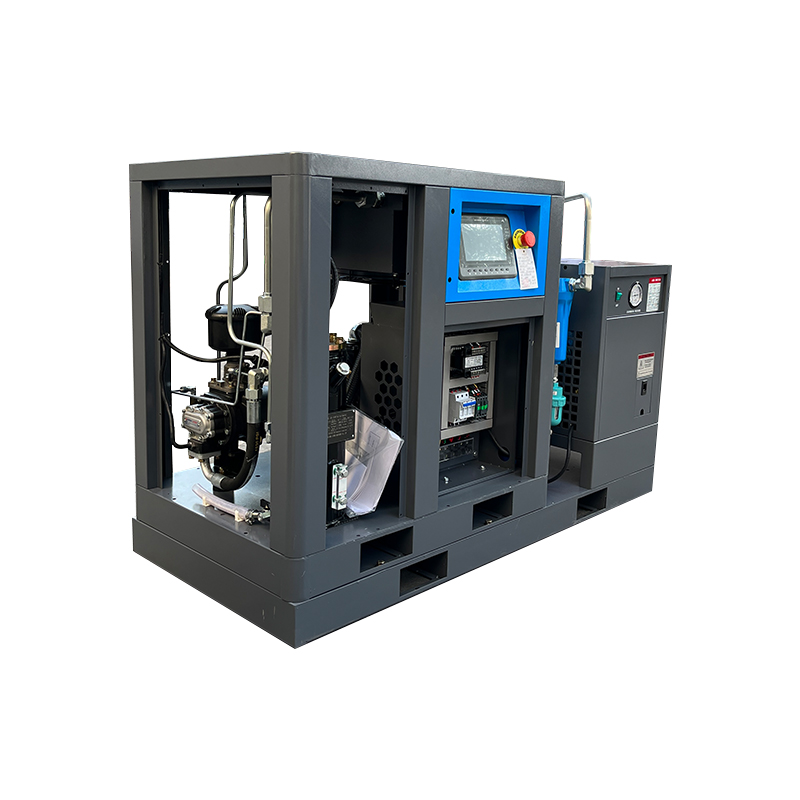

Why We Recommend ZAKF Two-Stage Air Compressors

For businesses that cannot afford downtime and seek to maximize their return on investment, the ZAKF Two-Stage Air Compressor stands out. Here’s why it’s the intelligent choice for forward-thinking operations:

Significant Energy Savings: The two-stage process is inherently more efficient. By cooling the air between stages, it reduces the work needed for the second compression, directly translating to lower electricity consumption—often by 15% or more compared to single-stage models. This saving compounds year after year.

Built for Continuous, Heavy-Duty Work: With a 100% duty cycle, the ZAKF compressor won't falter during long shifts or demanding applications. It’s engineered for the rigors of manufacturing, automotive repair, and woodworking.

Unmatched Durability & Lower Lifetime Cost: The reduced operating temperatures and lower thermal stress on components mean less wear and tear. The robust cast-iron construction ensures a long operational life, minimizing maintenance costs and unexpected breakdowns.

Cleaner, Drier Air: Cooler operation naturally condenses more moisture out of the air before it enters your lines, protecting your valuable pneumatic tools and end-products from water damage.

Is a ZAKF Two-Stage Compressor Right for You?

Consider a ZAKF compressor if your business fits this profile:

You operate your compressor for more than 4-6 hours a day.

Your energy costs are a significant concern.

You rely on compressed air for core production and cannot afford downtime.

You are looking for a long-term asset, not just a short-term tool.

Ready to Power Your Productivity?

Don't let an underperforming compressor limit your growth. Investing in a ZAKF Two-Stage Air Compressor is an investment in reliability, efficiency, and the future of your business.

Contact us today for a free, no-obligation consultation and let our experts help you select the perfect ZAKF model for your needs.

January 16, 2026

January 15, 2026

Compressors For Sale – High-performance, reliable air compressors at unbeatable prices! Ideal for industrial, automotive, and DIY use. Browse our wide selection of new & used models. Fast shipping,...

The HP Screw Air Compressor by HP is a high-efficiency, durable industrial air compressor designed for continuous operation in demanding environments. Utilizing twin-screw technology, it delivers...

Email to this supplier

January 16, 2026

January 15, 2026

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.